SFSU’s new Science and Engineering Innovation Center (SEIC) is a five-story, 125,000-square-foot building that serves as a hub for STEM education.

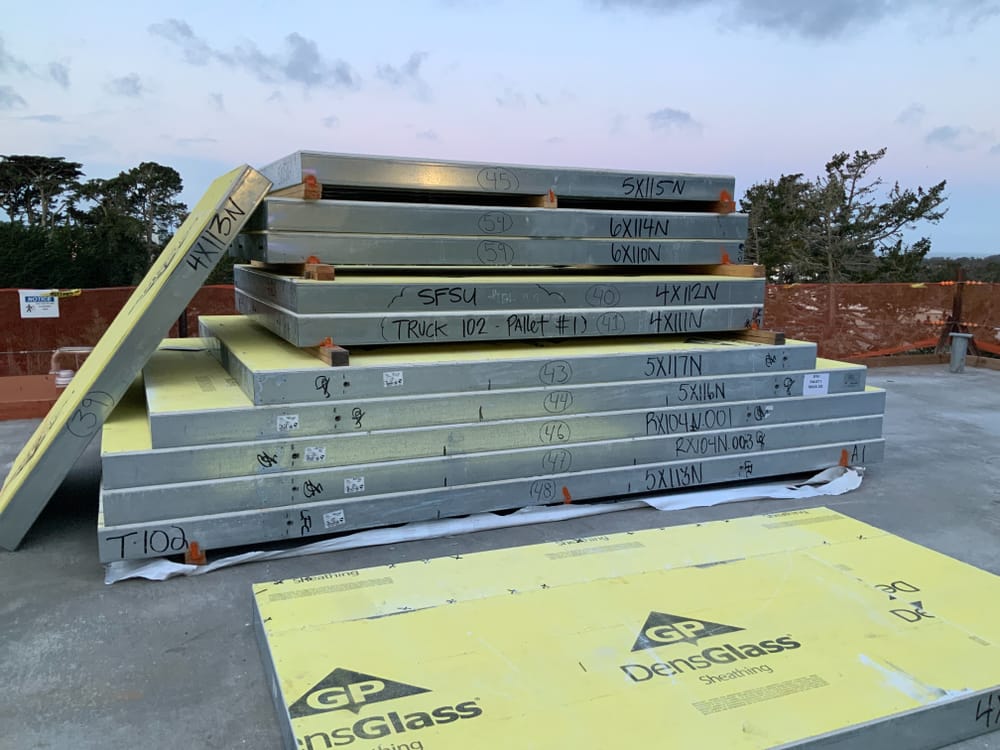

Digital Building Components was selected to prefabricate 42,000-sq.-ft. of exterior sheathed panels for the facility. Off-site manufacturing is a great option for active university campuses because it minimizes construction traffic and reduces risk for the surrounding community. It also minimizes the amount of required laydown space required, which was a big advantage due to the tight jobsite.

Prefabricating the exterior saved a significant amount of time compared to a traditional stick-built approach. The sheathed exterior panel scope was completed in only 13 days, averaging 12 panels per day.

During construction, the Bay Area region experienced severe atmospheric rivers that resulted in power outages and flooding. Even with these weather delays, the project was still on schedule because of the time savings when using a prefabricated approach.